General Information Post.

All the production Ford Motor Company U.S.A Ford Fairlane 221, 260, and 289 c.i.d. V8 engines made before about the late 1966 model year were manufactured in Cleveland, Ohio, U.S.A. and not in Windsor, Ontario, Canada.

Specifically, all High Performance 260/289 assembly line engines 1962-67 were manufactured in Ford Motor Company's manufacturing complex in Cleveland, Ohio, U.S.A. All original equipment new leaf spring chassis Cobra engines were "Cleveland" engines if one just has to cast them into a lump into one category.

There was no such thing as a "Windsor" small Ford V8 engine during new leaf spring chassis Cobra production based on all data collected to date. There were subsequent issues of 289, 302, and 351 c.i.d. V8 engines manufactured in Windsor, Ontario, Canada that were then actually "Windsor" engines.

Beginning in late 1966, thank you Bob Mannel for the clarification, Ford started producing 289 c.i.d. engines in Windsor, Ontario to join production from Cleveland, Ohio. Afterwards, Ford started making a new 1969 model year 351 c.i.d. engine in Windsor, Ontario but the "Windsor" colloquial name did not exist yet. During the year 1969 Ford introduced another new for the coming 1970 model year design 351 c.i.d. engine. Two very different engine designs with the same displacement and two different factories to make them. After the second new engine production started, the first model made in Windsor became known colloquially as the 351W model with W meaning it was produced in the Windsor, Ontario facility. The second design created for the upcoming 1970s model year was colloquially called the 351C model where C meant they were made in Cleveland, Ohio. It was confusing in 1969 and I recall the types of questions we asked the local Ford dealer at the time.

Somewhere along the line, authors started calling all the Ford Fairane 221/260/289 c.i.d. engines, "Windsor engines" which of course was not ever true. It would be more appropriate to say Cleveland production of 289 engines was joined by production in Windsor late in 1966.

Thanks again to Bob Mannel who helped with this timeline. Additional details are included in his excellent book.

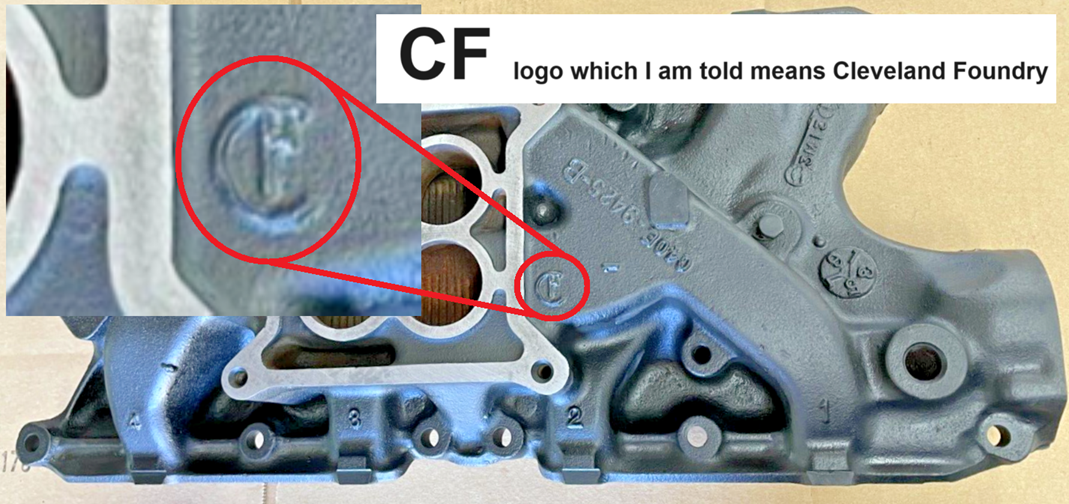

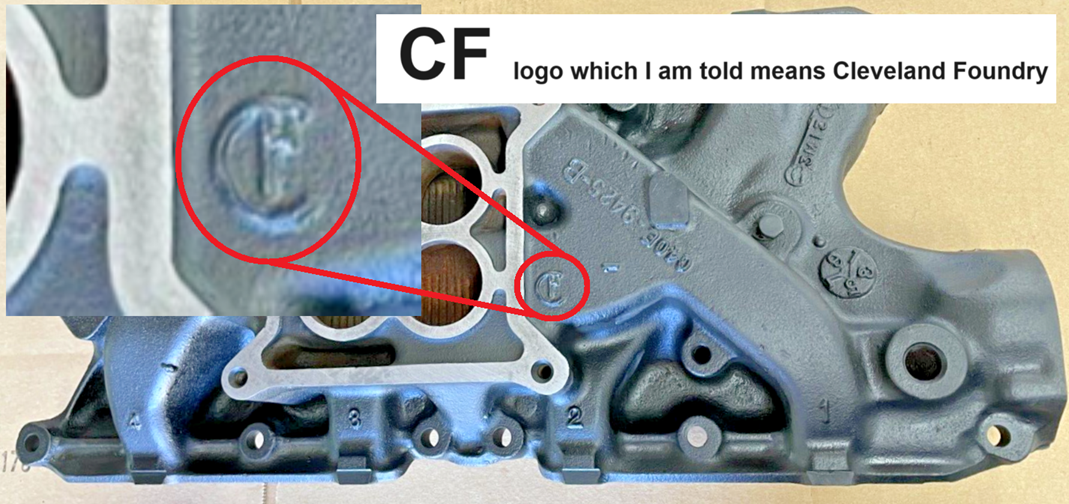

Here is a screen grab image of a cast iron Ford 289 intake manifold casting produced December 13, 1963. You might find one with that date in a new Cobra completed during late 1963 or early 1964. (Ford Fairlane series engines were painted Ford engine satin black before the 1966 and not this custom color.)

All the production Ford Motor Company U.S.A Ford Fairlane 221, 260, and 289 c.i.d. V8 engines made before about the late 1966 model year were manufactured in Cleveland, Ohio, U.S.A. and not in Windsor, Ontario, Canada.

Specifically, all High Performance 260/289 assembly line engines 1962-67 were manufactured in Ford Motor Company's manufacturing complex in Cleveland, Ohio, U.S.A. All original equipment new leaf spring chassis Cobra engines were "Cleveland" engines if one just has to cast them into a lump into one category.

There was no such thing as a "Windsor" small Ford V8 engine during new leaf spring chassis Cobra production based on all data collected to date. There were subsequent issues of 289, 302, and 351 c.i.d. V8 engines manufactured in Windsor, Ontario, Canada that were then actually "Windsor" engines.

Beginning in late 1966, thank you Bob Mannel for the clarification, Ford started producing 289 c.i.d. engines in Windsor, Ontario to join production from Cleveland, Ohio. Afterwards, Ford started making a new 1969 model year 351 c.i.d. engine in Windsor, Ontario but the "Windsor" colloquial name did not exist yet. During the year 1969 Ford introduced another new for the coming 1970 model year design 351 c.i.d. engine. Two very different engine designs with the same displacement and two different factories to make them. After the second new engine production started, the first model made in Windsor became known colloquially as the 351W model with W meaning it was produced in the Windsor, Ontario facility. The second design created for the upcoming 1970s model year was colloquially called the 351C model where C meant they were made in Cleveland, Ohio. It was confusing in 1969 and I recall the types of questions we asked the local Ford dealer at the time.

Somewhere along the line, authors started calling all the Ford Fairane 221/260/289 c.i.d. engines, "Windsor engines" which of course was not ever true. It would be more appropriate to say Cleveland production of 289 engines was joined by production in Windsor late in 1966.

Thanks again to Bob Mannel who helped with this timeline. Additional details are included in his excellent book.

Here is a screen grab image of a cast iron Ford 289 intake manifold casting produced December 13, 1963. You might find one with that date in a new Cobra completed during late 1963 or early 1964. (Ford Fairlane series engines were painted Ford engine satin black before the 1966 and not this custom color.)